Pen Feeds: Types, Mechanism, And Role In Ink Delivery

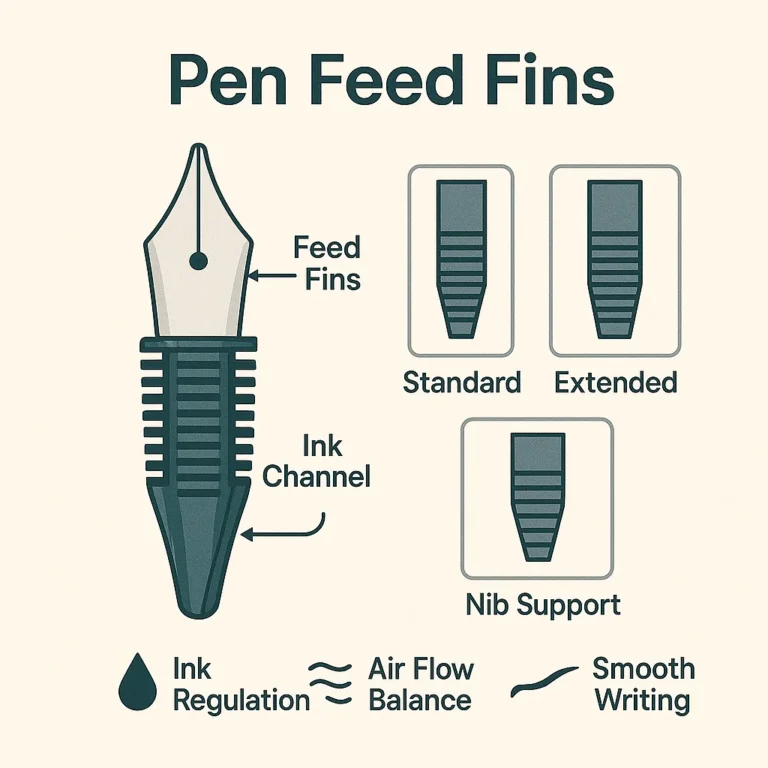

Pen feeds control ink flow from the reservoir to the writing tip, ensuring smooth and consistent delivery. They come in various types, such as ebonite and plastic, each with unique channel structures and flow mechanisms. The feed’s design plays a vital role in balancing ink and air, directly impacting writing performance.

Key Takeaways

- Pen feeds move ink to the nib through capillary action for smooth writing.

- There are ebonite and plastic pen feeds. Ebonite lasts longer and offers quality, while plastic is common in modern pens and works with many ink types.

- The design of a pen feed, like its grooves or channels, affects ink flow speed, changing your writing experience.

- Cleaning the pen feed regularly prevents clogs and keeps ink flowing steadily.

- Knowing how your fountain pen’s feed works helps avoid problems like skipping or leaking.

What is a Pen Feed?

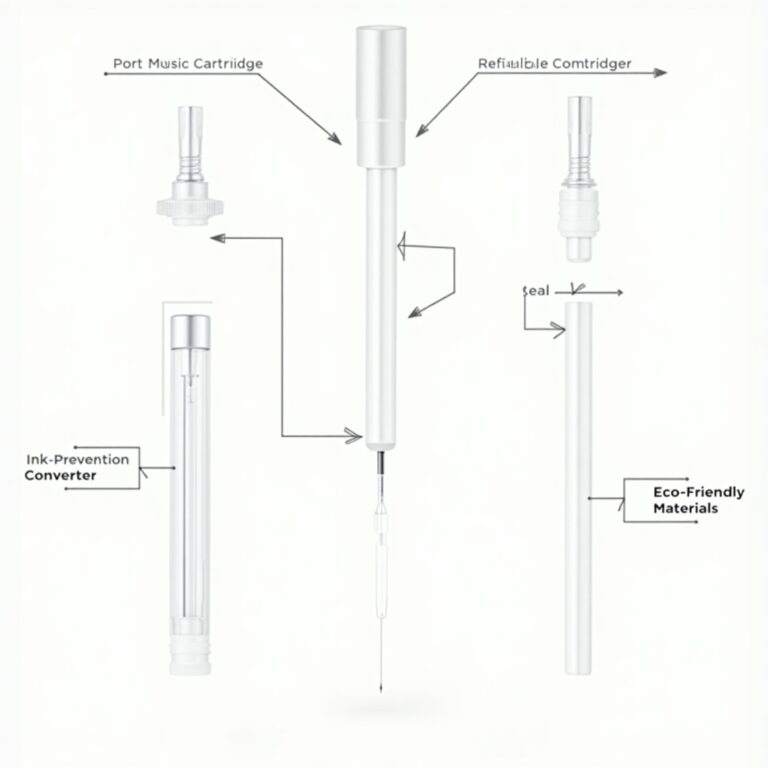

A pen feed is a critical part of fountain pens. It moves ink from the reservoir to the nib, touching the nib to transfer ink onto paper. The feed uses capillary action, similar to plants drawing water up their stems.

This mechanism also allows air into the ink chamber to keep the ink flow steady.

Pen feeds have various shapes but all feature grooves or channels that guide the ink smoothly during writing. They fit tightly under the nib, ensuring consistent performance of your fountain pen every time you write.

Types of Pen Feeds

Ebonite and plastic feeds in fountain pens are crucial for moving ink smoothly from the reservoir to the nib.

– Ebonite feeds help ink flow consistently, enhancing writing quality.

– Plastic feeds play a key role in controlling ink delivery to the fountain pen nib.

Ebonite Feeds

Hard rubber, known as ebonite, is used to make feeds for fountain pens. These are stronger than plastic feeds. The small channels in ebonite feeds help move ink smoothly from the reservoir to the nib, ensuring continuous writing without interruptions or smudges.

Pen enthusiasts like ebonite feeds because they last a long time and handle ink well. They’re best for high-quality writing instruments that need reliable ink flow. Cleaning them is easy too, which helps with pen maintenance.

Ebonite feeds are common in expensive pens and provide a smooth writing experience.

Plastic Feeds

Contemporary fountain pens usually feature plastic feeds as opposed to the traditional ebonite ones. Plastic is more economical, serving manufacturers who aspire to cut down costs.

These feeds work perfectly with both bottled ink and ink cartridges, fitting comfortably in the pen’s grip section to direct ink to the nib.

Plastic feeds guarantee a steady ink flow. They’re fabricated through injection molding, a process that ensures exactness and consistency. This production method favors pen aficionados by offering reliable ink flow in cost-effective writing tools.

Plus, plastic feeds adjust effectively to a range of ink kinds, backing diverse writing styles and preferences proficiently.

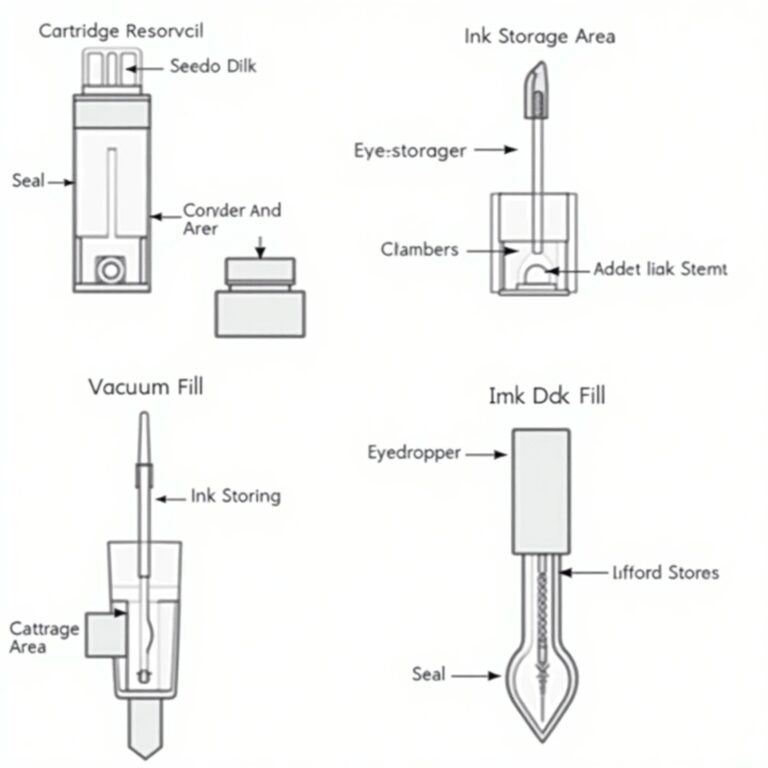

Mechanism of Ink Delivery in Pen Feeds

Pen feeds move ink to the nib using capillary action, balancing ink flow with air for smooth writing. This method helps fountain pens write consistently.

Capillary Action

Capillary action helps your fountain pen work by pulling ink through the space between the feed and nib because of surface tension. This is similar to how plants draw water up their roots.

For fountain pens, this action moves ink against gravity to the tip for writing.

This process also keeps ink flow steady and prevents air vacuums that could stop the flow. Because of capillary action, brands like Sheaffer and Waterman ensure smooth writing with a balance of air and ink in both modern fountain pens and cartridge pens.

Airflow Control

Air moves into the ink reservoir to replace ink used during writing. This balance ensures a steady ink flow from the fountain pen nib. If not balanced, the pen won’t write properly.

The breather hole near the nib lets air enter and travel through the fountain pen feed. This helps manage the air exchange needed for consistent writing. Modern fountain pens are designed to maintain this balance, offering a smooth experience for users.

Too much or too little air can disrupt how well you write with these pens.

Role of Pen Feeds in ink delivery

Pen feeds are crucial for moving ink from the reservoir to the paper. They rely on capillary action, like a small straw pulling up liquid, for smooth ink flow during writing. Pen feeds feature a breather hole that allows air into the ink chamber to facilitate this process.

The feed system is central to a fountain pen’s function, ensuring consistent ink distribution. Made from plastic or ebonite, these materials are key in managing how the ink flows and adjusts to match your writing pace.

The design of the feed determines the rate at which ink is released, maintaining an equilibrium that prevents blotching or dry patches as you write.

Conclusion

Pen feeds are crucial for fountain pen operation. They rely on capillary action to move ink from the reservoir to the nib, managing airflow for smooth ink flow. There are two types: ebonite and plastic feeds.

Ebonite feeds, traditional in design, are known for their quality. Plastic feeds, more common in modern pens, offer durability and easy maintenance. Knowing about these parts helps you pick the right pen and maintain it properly for a better writing experience.

FAQs

1. What is a fountain pen feed and what role does it play in ink delivery?

A fountain pen feed is a crucial part of modern fountain pens, controlling the ink flow from the ink reservoir to the nib. It uses capillary action and surface tension to ensure smooth writing.

2. How do proprietary ink cartridges work with the pen feeds?

Proprietary ink cartridges are designed specifically for certain brands or models of fountain pens. They fit into the grip section of these pens, supplying bottled ink directly to the feed and then onto the nib.

3. Can you explain how capillary action works in a plastic feed?

In a plastic feed, capillary action refers to how liquid moves against gravity due to surface tension. The small channels inside allow this process, pulling up the ink from an attached cartridge or reservoir towards the nib.

4. Why is maintenance important for fountain pen feeds?

Maintenance prevents clogging issues that can disrupt your writing experience by affecting consistent ink flow. Regular cleaning ensures optimal performance of your writing instruments – be it quills or advanced models like those using proprietary cartridges.

5. Are there different types of feeds used in various kinds of pens?

Yes! There are several types including breather hole designs popular among pen enthusiasts as they help maintain balanced air pressure aiding smoother delivery of bottled-ink through their respective paths.